Best ERP Software for Discrete & Process Manufacturing Industries

Manufacturing ERP Software is an integrated set of software suites that allows manufacturers to seamlessly integrate their resources and flow of information within the organization.

ERP stands for enterprise resource planning i.e. quite simple and easy to understand as Enterprise Resource Management.

The software is often used by large enterprises for lean manufacturing, inventory control, and replenishment planning.

But today ERP means more of a cloud-based ERP where both apps and data are available online and hosted on the cloud.

And it is adding more value and space for Small and Medium Enterprises as well in real-time.

Managing the resources of an Enterprise requires the establishment of several departments within an organization or business.

Every department has its own process and flow of information that is either independent or dependent on another department’s outputs and processes.

Thus all these departments collaborate and work together to manage small or large units called Enterprise.

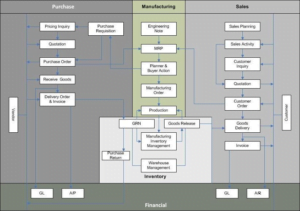

For example, consider a manufacturing unit with various departments that process various functions such as Purchase, Production, Job Work, Quality, Plant Maintenance, Warehouse, Raw Materials, Consumables, Scrap, Subcontracting, I.T., Marketing, Sales, Finance, etc.

ERP Software, also known as the ERP system or ERP Suite simply integrates all these processes into a single system.

Here is an ERP flow chart for your reference, check out how an ERP system engages and collaborates with each department within an Enterprise.

Defining Manufacturing ERP Software

Manufacturers operate in one or more modes such as Made to Stock, Make to Order, Engineer to Order, or Customized to Order.

Regardless of the modes, the manufacturing industry always goes through complex and constantly changing processes.

Therefore manufacturers of almost every size need a manufacturing ERP.

Manufacturing ERP automates, tracks, collaborates, and connects every step in a dynamic manufacturing process, from receipt of an order to shipment of the order.

Manufacturing ERP also provides real-time visibility into every part of your manufacturing or distribution business.

These are industry-specific applications that come with advanced functionality for manufacturing.

And connects back-office processes with the shop floor also called the manufacturing plant.

Manufacturing ERP Software also offers a specific solution based on the manufacturing domain such as:

- Specific manufacturing needs with deeper and more advanced functionalities for manufacturers

- Give a 360-degree view of the entire manufacturing process from the top floor to the shop floor

- Integrates, streamlines and automates core business processes with the manufacturing processes

- In-depth manufacturing control via capacity planning

- Improved efficiency and profitability that allow manufacturing businesses to be profitable

- Less customization in terms of industry fit

- A complete business management platform from a single database

Features of ERP Software for Manufacturing

Most manufacturers fail to identify a manufacturing ERP, not all ERP software caters to the needs of a manufacturing business.

So how do you identify a manufacturing ERP?

95% of manufacturers believe that ERP software should integrate shop floors across the value chain.

But, it is not so when it comes to generic ERP versus manufacturing ERP.

ERP software that is generic connects only the Accounting, Sales, Purchase, Inventory, CRM, and E-Commerce integration to some extent.

However, a manufacturing ERP connects a Shop Floor for production management extensively.

Production Control and management are the real deal when it comes to a manufacturing ERP.

Therefore a manufacturing ERP should contain some of these basic features such as:

- Multi-Level Bill of Material

- Master Production Schedule

- Material Requirement Planning

- Enhanced Inventory Management

- Warehouse Management

- Capacity Requirement Planning

- Advanced Planning and Scheduling

- Production Management

- Plant/Machines Maintenance

- Quality Control

- Quality Assurance

Why is manufacturing ERP important for Manufacturers?

Nothing is more complex than a manufacturing business.

From managing your core manufacturing process to your daily business process a manufacturing ERP tracks raw materials, allocates resources, and plans out the production.

An MRP engine is the heart of a manufacturing ERP that automatically pulls raw materials availability and tracks the shortage of overall materials.

Based on that information it automatically creates a default list of job orders and purchase orders ensuring exactly when a process should start and end.

From raw materials, and consumables to finished goods the availability of resources on time actually streamlines manufacturing businesses.

To bring out efficiency in production, manufacturers need a lot of resources from the availability of idle machines on the shop floor to the availability of labor, finished and semi-finished stock to raw materials inventory.

However manual processes and stand-alone programs cannot answer effectively what is going on in enterprises at the right time.

The shop floor is that execution area that actually needs the right resources and right information at the right time for profitable manufacturing.

That is where a manufacturing ERP comes which actually provides the answers you need to questions bombarded immediately after orders are received from your customers.

A manufacturing ERP provides transparency on what resources are available and what is not so business owners can decide

- What do I need to make?

- When do I need to make it?

- What do I need to purchase to make it?

- When do I need to purchase it?

- How do I ensure the required quality?

- How do I make it efficient?

- What is the cost of making it?

- Is it profitable for my business?

11 Best Manufacturing ERP Software for Discrete & Process Industries

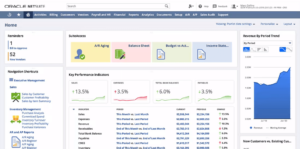

1) NetSuite

NetSuite ERP software is a cloud-based complete business management solution for enterprises.

It enables companies to operate their work more effectively with automated core processes and provides real-time financial and operational performance visibility.

It also has a particular integrated suite of applications that manages accounting, inventory, order management, production, supply chain, and many other works.

NetSuite ERP software gives businesses complete transparency and visibility for their data and strict control over their businesses.

The company provides SaaS and on-premises ERP systems for mid-level to large companies for many businesses.

Oracle owns NetSuite and it has extensive offerings that give modular solutions to the manufacturing industry.

This software is commonly used by over 40,000 companies worldwide when enterprises use its licensed version.

It is constantly updated with time and is an affordable subscription plan.

With NetSuite ERP software, you can manage multiple businesses, units, and legal entities.

The software is run by businesses in more than 200 countries, it supports 27 languages and 190 currencies that manage businesses globally.

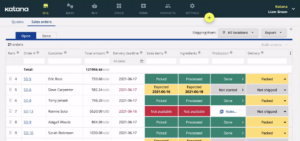

2) Katana MRP Software

Katana is a cloud-based MRP software that helps small businesses streamline their manufacturing process.

It gives users the ability to manage their inventory, create and track production orders, and track machine utilization.

Katana also provides real-time visibility into all aspects of the manufacturing process, from raw materials to finished products.

A powerful and comprehensive software solution that was designed to streamline and optimize manufacturing processes.

Katana’s robust MRP capabilities are some of the most advanced in the industry, and the software is capable of supporting businesses of all sizes.

The system has an intuitive interface and extensive functionality making it one of the most user-friendly software.

This MRP software can also help businesses optimize their inventory levels and forecast future needs.

Track on-hand, committed, and expected stock amounts in real time and monitor your inventory across multiple warehouses.

Katana also extends its capability beyond manufacturing providing total visibility and managing all the moving parts of your business — inventory, sales, production, and beyond.

Connect directly to your sales channels such as Shopify and WooCommerce as well as your financial systems like Quickbooks Online and Xero to enable complete control over your manufacturing business.

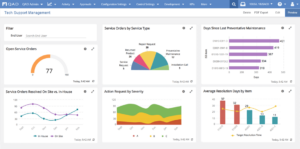

3) Acumatica ERP Software

Acumatica is the best choice if you want to streamline your business.

There is no shortage of solutions because Acumatica offers multiple software editions for businesses in all shapes and sizes.

If you are doing business on a low scale, mid-term level, or having a huge company running worldwide, you can take benefit of usage-based pricing to keep the cost low.

It does not matter how you are doing your business, Acumatica cloud-based ERP software gives high–end features for each company.

With its tool, you can handle different industry sectors like financial management, business intelligence, accounting, and stock management.

From midmarket businesses to small businesses who want to enhance their businesses, it provides incredible choices because it gives flexibility, adaptability, and ease of implementation.

In Acumatica ERP software, there is also the feasibility of adding more functions to your current software as per your business requirements.

As your business grows, it grows along with it. So you have to pay only for those that you require.

The software usage-based pricing makes it affordable for multiple users.

You are not required to pay extra for adding new users, so it is easy for you to onboard your team.

4) QAD

QAD ERP software combines deep manufacturing ERP and supply-chain proficiency with an advanced platform and user experience.

It enables the manufacturers to effectively give repose to changing their businesses and provide the precise expertise of using and running safe, dependable global cloud ERP.

It is a popular manufacturing solution for giant and high-performance businesses from automobiles to chemicals or any manufacturing company.

The most crucial component for any manufacturing ERP is its configuring flexibility.

And QAD is one of the best-known ERPs in the manufacturing domain with high-end configuring capability.

This manufacturing ERP software has been there for more than ten years as a cloud-based business management application.

The software helps the manufacturer efficiently maximize the return on their ERP investment, enabling them to achieve a considerable level of fit today and quickly respond to changes tomorrow.

Industry best experts create it through deep research. Its result is faster implementation and the best suitable out of the box.

It is built on QAD companies’ portal, enabling them to develop and streamline last-mile functionality that gives manufacturers their competitive advantages.

QAD makes it simple to customize and recode the module inside the software with its extra customization facility.

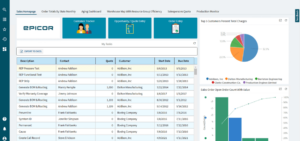

5) Epicor ERP Software

Epicor is making its transformation to the cloud space along with others.

It creates a new type of transparency and is an absolute ERP software for manufacturing operations that is beneficial for businesses.

Epicor software allows companies to choose to buy what they require and the flexibility to add more features later.

The software provides management to the production department, supply chain management, financial management, and scheduling.

The software is easy to customize and scalable, and it is also compatible with mobile.

Epicor software also provides a Quality Performance Management module that is not available in any other ERP software.

This kind of module is not only obtainable through Independent Software Vendors in engaging with other platforms.

With Epicor, you have the choice to deploy the software as cloud-based SaaS or on-premise.

In addition to the business-specific ERP software, it also provides its services to other business needs like:

- Business intelligence and analytics

- Scheduling and planning

- Customer relationship management

- Business content management

- Financial management

- Data management

It has been serving its manufacturers for over 40 years and produces flexible ERP suitable for a wide variety of businesses, including MTO, ETO, mixed, and many more.

It is specifically best for highly technical companies like defense, medical, and aerospace.

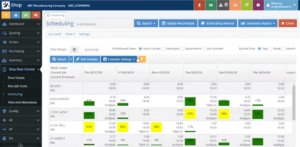

6) E2Shop System

The E2Shop system helps the shop proprietor effortlessly manage all aspects of business operations and manage profits.

Whether it’s your front office or shop floor that you are worried about, the fully functional E2Shop system removes the threat of uncertainty from shop management.

The software is created while remembering that it provides you with optimal control of your shop operations.

This ERP system also has the flexibility to improve how, when, and where you use all of your business data.

The E2Shop system contains features that are not available in any other software system.

The quality makes the software amazingly comprehensive and user–friendly.

It presents all the data in a relevant and informative format that you can access in seconds.

It also gives your business management control at your fingertips, from estimation, quotation, job scheduling, and hitting the clients on the due date.

The E2Shop software employee DC mobile app and E2Shop touchscreen tablet app help to track the work on the shop floor.

And getting connected to this software will surely help to save you time and stress.

7) Rootstock

Rootstock software is built on the Salesforce platform to leverage strong cloud choices and quality integration among all applications.

It enables scheduling of production, shop floor management, stock management, purchasing, and financial management.

It also offers engineering alterations like sales management, services, return, and repair.

This wide selection of choices can be utilized to add applications and solutions inside the Salesforce ecosystem to customize and focus on the requirements of businesses.

Rootstock has some new elements for CAD and engineering that enable it to manage designs for electrical, mechanical, and electronic functions.

The work order can change without any worry to standard routings that give shop floor management the flexibility to customize production orders without any problem.

To typically bring on special requests and customize production, Rootstock has some solid costing potential from small to significant levels.

8) DelmiaWorks (Formerly IQMS)

Unlike other software that tries to help various types of businesses, IQMS is centered around core manufacturing.

It is designed to provide solutions for the manufacturing industry, including medical, automotive, defense, stamping, contract manufacturing, packaging, production of BOMs, and many more.

IQMS also provides dozens of manufacturing-specific components to take your ERP software even further, including tons of other tools to streamline your complete operations.

Ultimately, this entire solution creates end–to–end visibility and control for shop floor methods for business resource planning.

IQMS is the best choice if you are interested in scalability, enhancing efficiency, productivity less downtime, and increased prospect.

Since its starting inception, this ERP system has been used by manufacturing companies for a long time.

This software is appropriate for all kinds of businesses from mid to small to significant, and its biggest advantage is its functionality in the manufacturing business.

The software helps companies that have complexity in their supply chain to optimize benefits from it.

It is also easy to change what is suitable according to your requirements without changing the complete coding.

The built-in feature in this software allows the development of seamless automation in buying from time to place an order through the delivery of raw materials and critical elements.

So it is the best choice for companies who try to build lean best practices into their buying process.

And as an IQMS customer, you can see various benefits with this ERP software:

- Reducing inventory costs

- Optimized plant floor output

- Quick return on investment (ROI)

- Efficient team communications

- On-time delivery based on demand

- Enhanced efficiency and shop floor first method

- Compliance management

If you are in need of manufacturing ERP software or manufacturing execution software (MES), IQMS is the best choice regardless of the business.

9) Plex: ERP Software for Manufacturing

Plex is an on-cloud enterprise resource planning (ERP) system that serves both discrete and process manufacturing businesses.

Therefore It enables manufacturers to manage their daily business operations and routines.

The solution is suitable for companies using lean manufacturing principles that use features like inventory control and build grave traceability.

They are ideal for manufacturing businesses rather than any other sectors of businesses and organizations.

Plex is deployed in the cloud and measurable to meet agile facility requirements.

Employees can also access the Plex mobile app to store data, update their work orders, and perform other tasks.

Plex software manages business accounting and financial management functions like cost accounting, business financial reporting, fixed assets, and sales tax calculations.

Plex also helps with the creation of centralized portals for tasks like accounting, buying and selling, and cash management.

Therefore this ERP system has many benefits in manufacturing:

- Designs that manufacturers create with multiple years of experience in the sector.

- Have the capability to respond to customers, market, or other changes.

- Customizable choices for unique requirements.

- Access to real-time data for making better decisions.

Plex targets many business sectors like automotive, food and beverage, industrial, fabrication, aerospace, plastic, and rubber.

10) SysPro ERP Manufacturing

SYSPRO manufacturing software enables ERP functionality that can be customized to measure the size of a business.

It also offers extra modules that can be added in the future as your company grows.

SYSPRO has common elements of manufacturing ERP systems like shop floor control, inventory management, and finance functions.

The system also provides solid scheduling functionality that helps in using single-constraint and multi–construction scheduling.

It allows the system to detect actual vs. estimated labor and streamline materials and scrap for work–in–process.

Therefore It is an essential tool for small manufacturers where the cost of materials can impact profit.

The system also has Engineering Change Control (ECC), so users can detect and manage the version in production.

SYSPRO provides end–to–end fully integrated business solutions that include accounting, stock management, planning, scheduling, supply chain management, warehouse management, customer relationship management, and many other businesses.

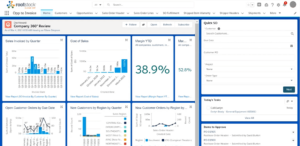

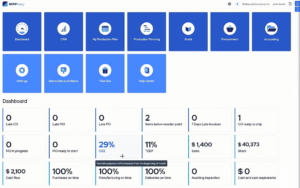

11) MRP Easy

MRPeasy is a manufacturing ERP software for micro-enterprises and the platform was built as an MRP2 system.

Its main features include manufacturing shop floor control, material planning, inventory, sales, warehouse management, and work management.

The software comprises production planning, CRM, procurement, supply chain management, and inventory management.

It also features a drag-and-drop scheduler that enables project managers to allocate resources in different jobs.

The procurement element allows companies to organize their purchasing process by streamlining each purchase cycle and buying orders.

MRPeasy combines lean manufacturing, serial numbers tracking, and manufacturing management abilities with order management and billing tools.

The CRM feature allows customers to access all customer information, account purchases, and history and also offers managers regular reviews on income metrics, marketplace reviews, and specific income data.

It also offers shop floor reporting, workers’ usage, and video display unit systems for the aerospace and protection industry.

The solution provides alignment between the engineering invoice of materials and the production routine.

This device can combine with QuickBooks and Xero and gives APIs for integration with different third-party applications.

All variations consist of an unlimited database and a limited-period free trial.

Conclusion:

Implementation of ERP software is a challenging, time-consuming, and expensive task.

However, ERP systems have changed a lot in recent software development from coding on the front end to deployment on the cloud and the ease of configuring the systems.

By selecting a cloud ERP platform, a manufacturing company usually invests in a product with a long lifecycle possibly longer than any other manufacturing tool.

This helps manufacturers identify loopholes, gain trust in ERP systems, and become profitable in the long run by streamlining manpower, machinery, capacity, and resource utilization at its best.

But whichever products or services you choose make sure it is in the best interest of you and your company.

After all, it should solve your problems, and your requirements and define your success.

6 Comments

Great Blog, Thank you

NetSuite ERP, customized by OpenTeQ Technologies for manufacturers, offers streamlined operations, real-time visibility, and scalability. With enhanced collaboration, regulatory compliance, and cost efficiency, it optimizes processes, fosters growth, and ensures industry-leading performance.

OpenTeQ Technologies is experts on NetSuite ERP

For More information about Manufacturing ERP & Management Software Reachout OpenTeQ OpenTeQ Services In USA

Interesting to know you guys are implementing NetSuite

Enterprise Resource Planning (ERP) software and systems used to plan, manage and deliver particular functionalities that support manufacturers and manufacturing operations are referred to as manufacturing ERP.

Great Justan

We are looking suitable Online Cloud Based ERP for Ethanol Production Unit.

Thank you for contacting us. Our expert team member will get in touch with you soon.